Project Management

Good project management ensures good quality.

Successful management of innovative molding processes has elevated our ability to deliver quality and performance with a global vantage point. Project Management is a dynamic process of bringing ideas, people and systems together for the specific purpose of achieving goals and creating solutions within time, cost and risk levels.

Each project manager is in charge of an appointed project and manages the progress of your project from beginning to end. Our professionally trained and well-connected teams will ensure you receive high quality products and consistent service, which in turn, will help you maintain a competitive advantage over your competitors.

The plant of HC-Mold Maker is certified ISO9001. This guarantees that we have a consistent and effective quality system in place to meet our customers' quality needs. We attach great importance on defining and documenting these needs for each part at the beginning of a project in order to minimize the errors once production is underway.

All phases contributing to part procurement and/or manufacture are fully documented. Copies of inspection results are forwarded with each shipment regardless of the quantity ordered.

Progress charts are issued every week by Email to our customers. These progress reports can also include photographs of the work in progress, making a real time tooling progress assessment service available to our customers.

Process Control

Process control is a key component in any manufacturing operation. In order to maintain plant efficiency and product consistency, a high priority must be placed on the monitoring and control of the variables which directly affect them. Process control has evolved from simple product monitoring functions to advanced planning, controlled implementation, review and refinement of significant processes throughout the organization.

HC-Mold Maker has implemented process control in all departments of its organization which contains a wide network of computer hardware and software resources to continuously monitor all aspects of its operation. The integration of real-time production monitoring, production scheduling, purchasing, inventory transactions, warehousing, labor and work order management, and preventive maintenance, allow for seamless communication and reporting between both internal HC-Mold Maker departments and its customers.

Each of our parts is assigned a full quality inspection plan, with a responsible leader from each of our key departments: engineering, tooling, processing and quality. These leaders work together to deliver the highest-quality part that meets-and exceeds-your needs.

Inspection Everywhere

Document and Data Control----to assure the most current data is being used.

Process Control----to ensure the part is correct the first time and each time thereafter.

Inspection and Testing----to avoid a poor quality part is passed on to the next step.

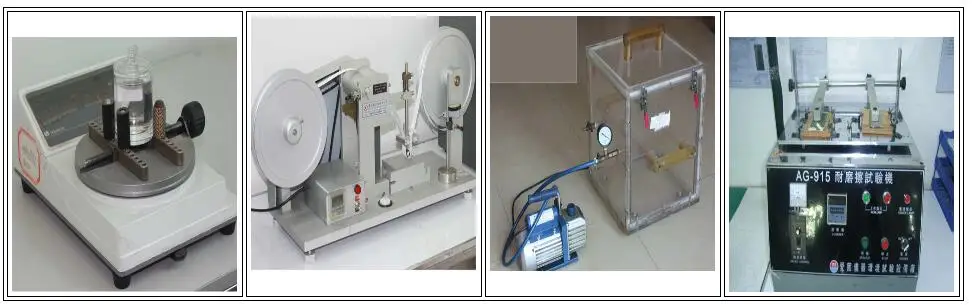

Inspection and Measuring Instruments and Equipment Control----to assure all test and inspection results are correct, uniform and meaningful.

Non-conforming Product Control----to avoid shipment of poor quality parts.

Handling, Storage, Packaging, Preservation and Delivery----to ensure customer satisfied with their product from order entry to final delivery.

Quality Control:

HC-Mold passed ISO9001:2000 Quality Management System and TS16949:2002...

Quality is the heart of a successful enterprise. HC-Mold designs and manufactures the products with advanced quality test methods and marvelous measuring facilities. We controls throughout the raw material test, process spot check regulations (total self-check, spot check by inspectors and technical re-test by groups), storages products spot test, every single step is controlled seriously. In addition, all employees are required to undergo strict training attend regular monthlyISO meetings to continually enhance the quality awareness thus ensuring the constantimprovement of the production process.

CASE STUDIES

Client: Thermoplan AG

Parts: parts for commercial coffee machine, milk tank, cover etc.

Project: 4 molds for 4 parts exported to Switzerland, insert mold, ultra sonic welding, hard tool of over 1 million circle time.

Material: PA12 (EMS Grilamid TR55 from Switzerland), PA6+PA66 (EMS Grillon TSM-30 from Switzerland), MDPE

Lead time: 30 days for 4 tools

Thermoplan AG is a famous Swiss quality coffee equipment provider. During their development of their new commercial coffee machine, we were responsible for 4 important parts- milk tank, cover etc.

We worked together with Thermoplan AG in their early design phase. Our rich experience of manufacturing has helped them to develop their products better, made their products more manufacturable, and lowered their cost of tool has made production more efficient. When they finish part design, they send it to our engineer. Our engineer will have a very detailed review to insure there is adequate draft, radii on internal corners, sink marks, air traps, distortion, undercut, and that the part will fill properly. In addition we review gating, ejection, parting line locations, water cooling layout, moving direction and distance of slide etc.

We have a very good communication with the engineer in Thermoplan AG. Our special ’check file?with picture, illustration and words are very helpful for clear engineering communication between us.

In order to make samples with the materials the final products uses, we import PA material from EMS company in Switzerland. PA12 is very expensive, high temperature engineering grade resin which is very difficult for molding. We invite EMS to our factory to discuss how to make the parts better. It provides very useful information for future production in Switzerland.

We begin the first shot for 4 sets of molds in 4 weeks.

Strong point: good communication

Milk tank for coffee machine

PA12 EMS Grilamid TR55

insert molding

Client: some famous tiny motor company in Germany

Parts: precise plastic gears for tiny motor.

Project: gears mold making and manufacturing.

Material: Dupont Delrin 525GR

Lead time: 30 days for 5 sets of gear molds

Our client offers the world’s largest consolidated portfolio of miniature and micro drive system technologies which specializes in the design and manufacture of complex, high precision miniature and micro drive systems for challenging areas of application like medical devices, handling automation, telecommunications, and precision optics. We provide our client high precision tiny plastic gears and other high precision parts. Tight tolerances on plastic gears are important for proper function and reduced wear. Our client focuses on understanding the customer’s requirements and provides customized micro drive system. So our challenge is to provide high precision gears in short time in order to coordinate with them to develop their system sooner and better based our rich experience of gears mold making and molding.

Strong point: experienced in precise and tiny parts

POM(Ticona Celcon M90)

POM(Dupont Delrin 525GR)

POM(Dupont Delrin 525GR)